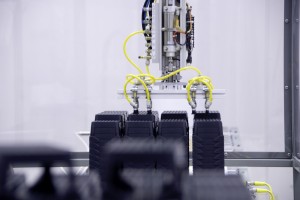

Triad Technologies employs the most modern equipment available for plastic injection molding. Our molding machines utilize All-Electric, servo driven CNC technology and provide precision never before seen in the injection molding world, providing high-efficiency, economical molding.

Triad replaces its injection molding machines every three years. This unusual practice is part of Triad’s commitment to always providing our customers with the latest equipment and technology available. The Plastics industry is evolving rapidly and we are committed to staying ahead of the pace. We are dedicated to always improving ourselves and the services that we offer.

As a result, your project will benefit from the latest new techniques and processes available. Brand new machines offer exponentially increased reliability and repeatability. They offer levels of efficiency and accuracy that can’t be approached by used and outdated equipment.

In addition, we also offer many value-added services, such as mold maintenance at no additional charge. Our enterprise management system counts every shot on every mold, and allows us to establish a maintenance program for your tools, a critical component of our overall philosophy.